Excellence Should Be The Goal!

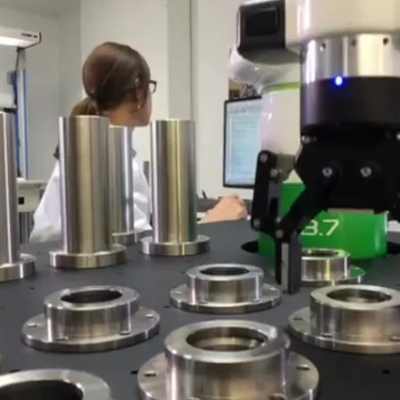

Optimum fabrication of steel flanges is essential to make them reliable and robust. When they are to be used in the manufacturing of collaborative robot arms, giving them the right shape is crucial. All engineers must understand the role played by testing. Doing it right is a vital part of the process. Designing the most suitable mechanism for this process is also crucial to the overall scheme of things. Compromising on strength is never smart. It must be understood that all individual parts in collaborative robots are essential irrespective of their size. As a result, opting for accurately finished and sturdy flanges become vital.

Joints matter

Flanges must be fabricated and welded correctly. The durability of all collaborative robots depends on the quality of flanges used. So, the use of inferior stuff will decrease the overall quality. The cobots may not function as per expectations in such a case. Joining different components of some collaborative robots will become a seamless process if correctly shaped flanges are used.

Don’t ignore fittings

Equal attention must also be paid to the accessories of the flanges. The fact is that these machines are only as strong as their weakest component. So, minute details must be considered at each step of the way. Manufacturers must ensure that only tested material certified for its strength and usability is used at all times. Check Here – About more uses of Steel Flanges.

Using Suitable Stuff As Per The Need

Different types of collaborative robots require specifically designed flanges in manufacturing. The treatment on the surface of the wedges and fittings matters a lot. These small parts have a significant role to play. The metal used in making flanges should also be taken into account to determine the ideally suited products for different collaborative robots.

Different types of collaborative robots require specifically designed flanges in manufacturing. The treatment on the surface of the wedges and fittings matters a lot. These small parts have a significant role to play. The metal used in making flanges should also be taken into account to determine the ideally suited products for different collaborative robots.

The cost of different type of flanges can vary if they are made from various alloys and metals. Using high-quality iron can be a good idea in most cases. However, moisture can cause rusting. As a result, most qualified engineers recommend the use of alloys like steel.

Do you want it lightweight?

Use of aluminum body parts and flanges can be the best way to get the optimum combo of sturdiness and lightness. Depending on the structure of the collaborative robots, their dependence on rims can vary. In some cases, a significant part of the total weight is contributed by flanges. Hence, finding the material ideal becomes of substantial importance.

The function

The crucial tasks to be performed by a machine must be taken into account to determine the optimum use of flanges. Use of products made from iron may not be a bad idea if there is zero possibility of the machine coming in contact with moisture. Using iron can also save a lot of manufacturing costs. In recent times, there has been a marked increase in the use of titanium in making high-quality flanges.

Ceramics and wood

Manufacturing flanges using wood remain a widespread practice. High-quality plastic can also be used on some occasions. Some of you might even be surprised to find out that ceramics is still among the prominent material used in making flanges. The insulative properties of ceramics can come in handy on multiple occasions. The increasing use of flanges in collaborative robots has been one of the crucial factors leading to the current state of affairs.

Always Select Products of Well-known Brands

When purchasing flanges, a lot of attention must also be paid to their manufacturers. Inferior quality products mar this industry. Companies such as Active Contact Flange have made a name for themselves by creating sturdy and robust products. They are also known for ensuring the suitability of their products as per the sector of the economy in which they will be used.

Use them wisely

Information about the multiple applications of collaborative will always be highly beneficial to engineers. Many people do not know about the extent of their usage in the automobile industry. Collaborative robots also find multiple uses in the aerospace parts manufacturer. Grinding of materials and providing them the right finish can be accomplished easily by suitable robotic arms.